This means that you will have access to each product’s current location, available stock, relevant purchase and sales orders, etc. With inventory tracking, you can view every single one of your products throughout its life cycle-from the moment they enter your warehouse or storage space, to the time they leave. Why do you need inventory tracking? Better stock visibility Reorder points are essential for preventing stockouts (situations where a seller runs out of stock). Reorder levelsĪ reorder point or level is the specific amount of stock remaining for a certain item at which it needs to be replenished or refilled.

#INVENTORY DEFINITION FREE#

Check out our free inventory turnover tool to calculate yours. Inventory turnover can tell you how your business is doing and whether you need to improve your sales strategy. A higher value represents stronger sales, and a lower value represents weaker sales. Inventory turnover is the rate at which your inventory is sold.

This can also help calculate your inventory turnover. Inventory valuation gives your leftover stock a financial value, which needs to be added to your balance sheet.

:max_bytes(150000):strip_icc()/InvetoryturnoverfinalJPEGreal-5c8ff4fc46e0fb00014a975c.jpg)

This is a practice that is used to calculate the value of unsold inventory when a business prepares their financial statements. Slow-moving inventory and dead stock are two main contributors to high carrying costs, so if you’re trying to reduce those costs, you’ll have to figure out a way to remove or sell the items.

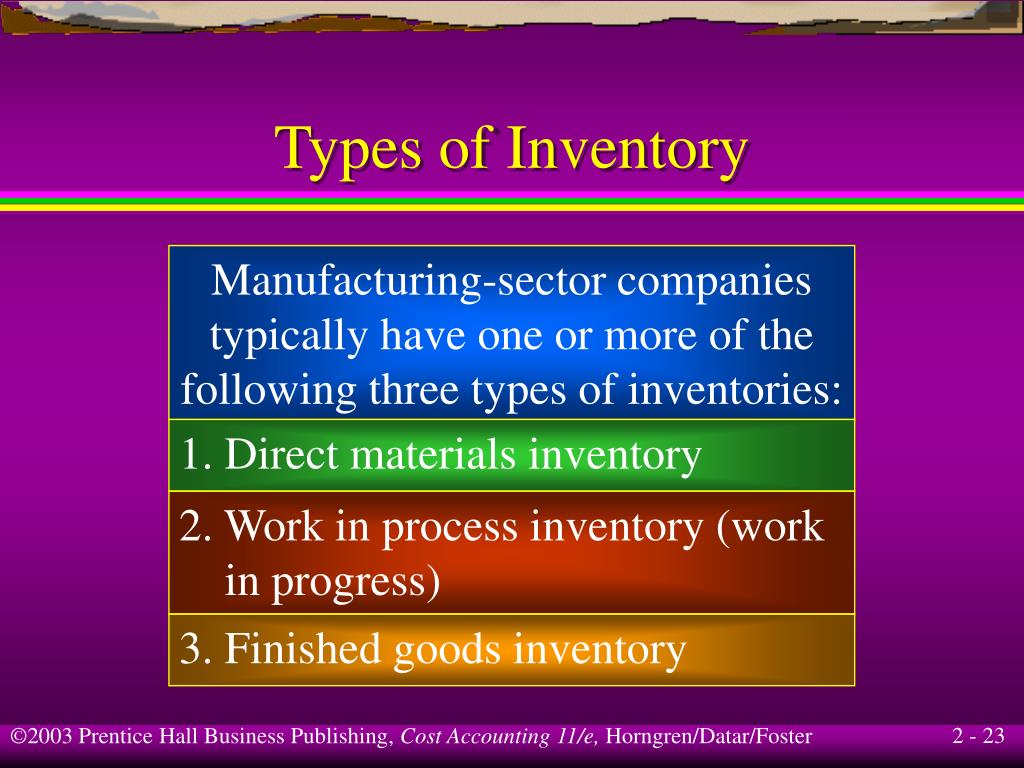

Carrying costs can tell you how long your business can continue to store this inventory before you begin to lose money because of it. This includes how much you spend on rent, labor, storage and relevant bills, and security. This refers to the total amount of money that is spent on storing, holding, and owning your inventory. Like your stock levels, inventory accuracy is essential for your business processes to smoothly function. Inventory accuracy will show you how big those discrepancies are. Ideally, both numbers should be the same, but because of reasons like theft, damage, miscalculations, and shortages from suppliers, there could be discrepancies. This is a KPI (Key Performance Indicator) that refers to the ratio between the quantity of inventory that has been tracked and the quantity of inventory that is physically present in your possession. Since your stock doesn’t remain in a fixed place, it’s important to keep track of its location so that you know where to find it if needed. (If it does, that means it has become either slow-moving or dead stock.) Once the stock enters your warehouse, it moves around as it’s first sorted and categorized, then stored, and then eventually retrieved and sent to the next stage of your supply chain. In a best-case scenario, your stock should not remain in one location for too long. Additionally, your stock levels provide a base for the other data that is tracked. It’s important to keep this data consistently updated so that you know whether you have enough stock for your business processes, whether they’re manufacturing new items or fulfilling customer orders. This value tells you how much of each item you currently possess. Typically, inventory tracking systems can monitor the following information: Updated stock levels Inventory tracking happens in every place of business that deals with inventory: manufacturing and production companies, warehouses, retail stores, etc. With inventory tracking, you have access to data such as your exact inventory levels, the location of each item or SKU, updated delivery statuses, and other inventory related information. Inventory has several definitions, but it most commonly means raw materials, unfinished goods, and ready-to-sell items. Inventory tracking refers to the process of a business continuously monitoring all of the inventory that it owns.

0 kommentar(er)

0 kommentar(er)